RS-201 Dual Diazo Type Direct Emulsion

- RS-201 Dual Diazo Type Direct Emulsion

-

- Features/Application

¡ñBest suited for fine line graphic images, transfer paper applications

¡ñExcellent resistance to water and superior durability

¡ñConsistent emulsion thickness profile over the mesh, Lower Rz value

¡ñGood adhesion to screen mesh

¡ñWider exposure latitude

¡ñRecommended for printing with water based inks and pastes

¡ñSuitable for T-shirt, Textiles and wider range of printing applications

Specifications

¡¤Viscosity: Approx.3000-3500 mPa・s,25¡æ

¡¤Solid Contents:Approx.40-41%

¡¤Packaging Standards:1kg set,5kgs set

¡ùContact us for custom packaging

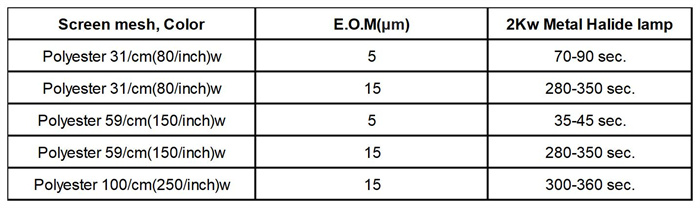

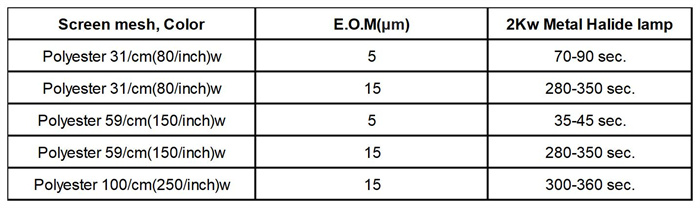

Exposure Data

The above is for guideline purposes only, kindly to use a gray scale exposure calculator to identify optimal exposure time.

Instructions

¡¤Wash, degrease and dry screen mesh. Remove grease and foreign contaminants with MSP cleanser.

¡¤Dissolve provided Diazo with 10% water to emulsion volume. Please do not use warm water.

¡¤Pour Diazo solution into emulsion. Mix it well. Prior to a use, let mixed emulsions settle for one day.

¡¤Or for immediate use, filter it with screen mesh 100/cm or higher.

¡¤Coat emulsion slowly in order to prevent air bubbles.

¡¤Dry coated screen completely at temperatures up to 40¡æ(104¨H)before exposure.

¡¾Remarks¡¿

¡¤Keep the mixed emulsion in a cool and UV light safe area. Use mixed emulsion within 2 weeks.

¡¤Recommended to filter remaining emulsion with screen mesh before pouring it back into the container to remove any dust, foreign substances and air bubbles.

Solvent Resistance Rating

¡ù24 hours swelling/absorption test results

-

PREVIOUS£ºRS-1400 Dual Diazo T

NEXT£ºRS-20 Dual Cure Type - BACK